OLEN is innovation born

A new concept. Innovative technologies.

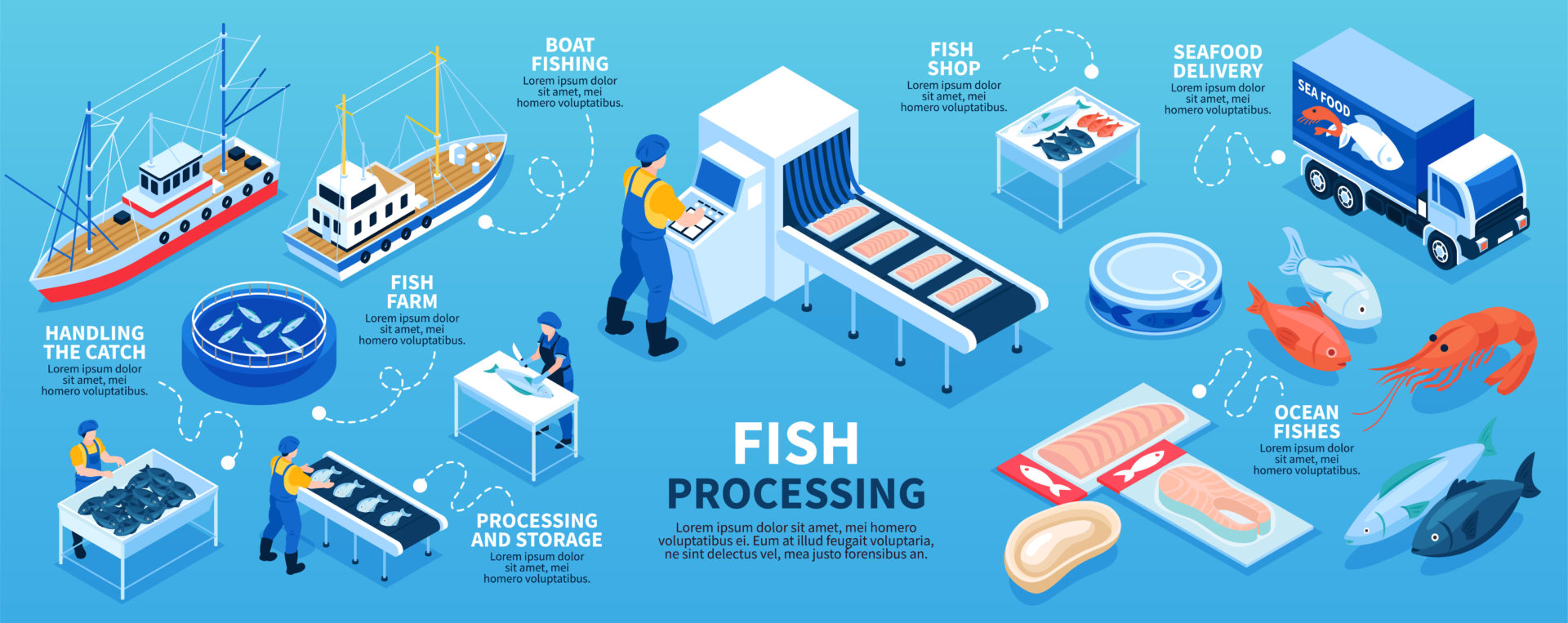

3 main scientific fields: metrology, business intelligence and the quality of seafood products.

A motivated multidisciplinary team built around SBV innovation. Synergy of skills to develop new prototypes, adapt existing solutions to meet customer needs.

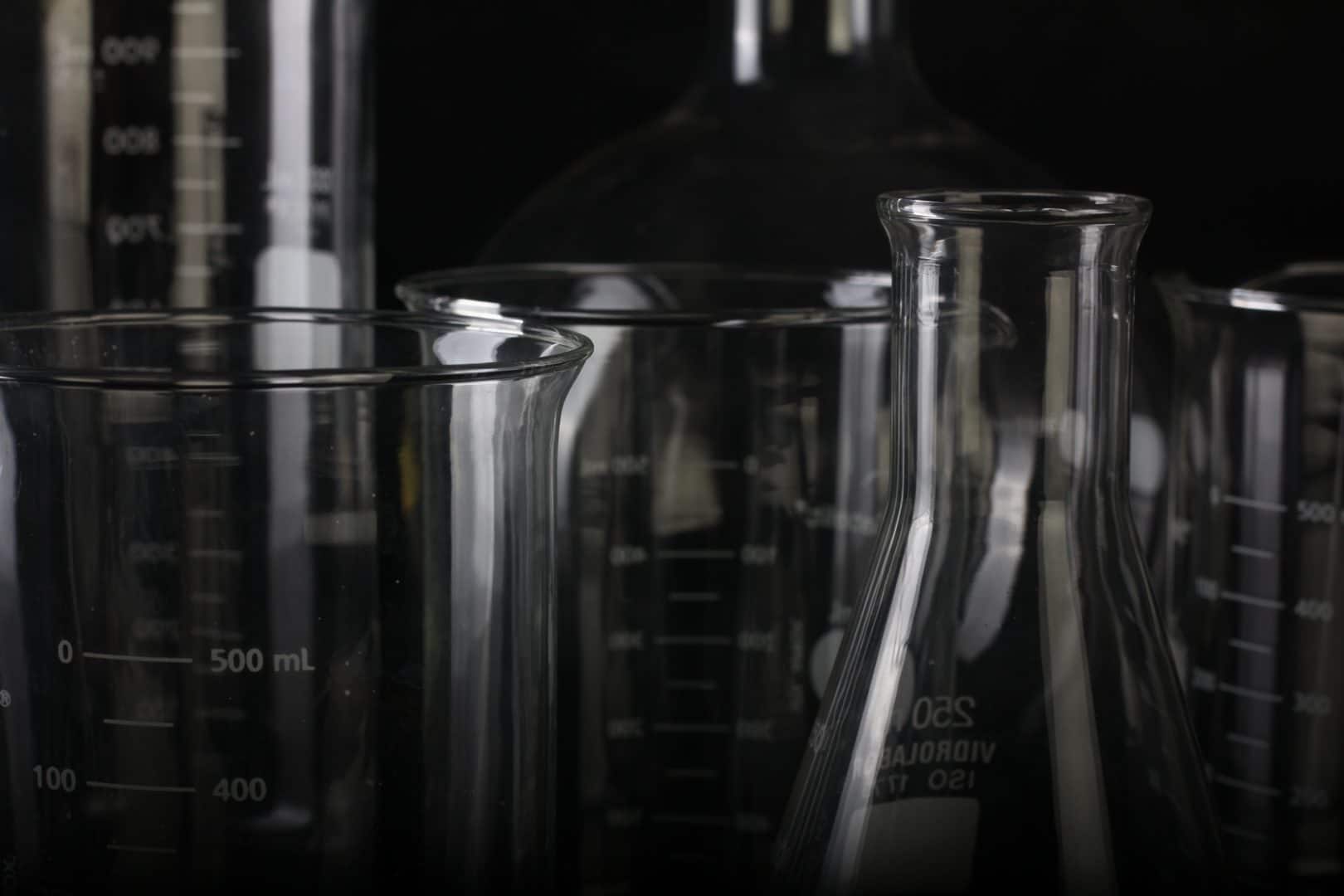

Metrology innovation

For several years, OLEN has been developing an innovative system for “in-situ” measurement of salinity in brines with a high salt concentration and very low temperature, used on tuna seiners to freeze fish. The system also measures the freezing temperature of brines as well as the temperature at which sodium chloride dihydrate appears.

2016

This project began in 2016 with a technical feasibility study conducted by the Pôle Cristal test and innovation centre specialising in refrigeration and climate engineering.

This project began in 2016 with a technical feasibility study conducted by the Pôle Cristal test and innovation centre specialising in refrigeration and climate engineering.

2017

Arrival of the Metrology engineer: Bruno Boulbry

2018

This was followed, over the period 2018-2019, by a laboratory prototyping phase and then “in-situ” tests during sea campaigns with the collaboration of the Compagnie Française du Thon Océanique (CFTO).

This was followed, over the period 2018-2019, by a laboratory prototyping phase and then “in-situ” tests during sea campaigns with the collaboration of the Compagnie Française du Thon Océanique (CFTO).

2019

This phase of the project was supported by the Brittany region through its “Inno R&D” innovation aid scheme and was the subject of a patent application in 2020.

This phase of the project was supported by the Brittany region through its “Inno R&D” innovation aid scheme and was the subject of a patent application in 2020.

2020

Since then, OLEN has continued to improve the accuracy and reliability of its measurement system through a rigorous metrological approach.

Since then, OLEN has continued to improve the accuracy and reliability of its measurement system through a rigorous metrological approach.

2021

Since 2021, OLEN is a member of the CFM (Collège Français de Métrologie).

Since 2021, OLEN is a member of the CFM (Collège Français de Métrologie).

Business intelligence at OLEN

We use business intelligence to provide decision support and allow decision makers to have an overview of the activities carried out. We develop and deploy a scalable software and hardware architecture capable of monitoring the salinity and temperature of the tanks according to the configuration of the vessel. The architecture integrates with the ship’s network to provide flexibility in the restitution of heterogeneous data.

User interfaces (UI) adapted to the different fishing methods confronted with the study of the data are developed in the form of a modern web page.

The development of the SBV system will revolutionise the world of brine freezing.

New fish preservation procedures are made possible by the use of the SBV system. To help customers implement these new procedures, Damien Dugay has joined the OLEN R&D team to provide his expertise on the conservation of fish in brine and dry.

Discussion with Damien Dugay, R&D engineer at OLEN.

How did you get to OLEN?

Following a preparatory class for the “Grandes écoles” in Nantes (BCPES: Biology, Chemistry, Physics and Earth Sciences) and an engineering course in agri-food at Agrocampus Ouest in Rennes, I had the chance to gain experience in various fields, such as quality (fish oil refinery) or R&D (shellfish sensometry in New Zealand). I then worked six years for Sapmer in Mauritius, where I was in charge of supplying the frozen tuna factory; then in Concarneau, in product development. The diversity of these experiences has enabled me to develop transversal skills to better understand the challenges in the field of fisheries and the valorization of fish and food products. As soon as the opportunity arose, I was able to join OLEN in 2020.

What role do you play in the company?

At Olen, I am a research and development engineer. I’m in charge of the “Agri” part. My role is to optimize the application of the technologies we develop, as well as their use in the field of fisheries today, and more generally in the agri-food industry of tomorrow.

What does an R&D engineer at OLEN work on?

I am currently working on projects to enhance the use of SBV technology to improve the quality of fish on board tuna seiners, as well as on projects to optimize the sardine brining process in a large Breton cannery.